Produce several plastic parts, including the floor mounted battery box and control boxes for a prototype electric scooter designed for the mobility impaired. All the plastic parts had to be capable of withstanding very rough use and be available in custom -colored high density polyethylene plastic. The customer needed short delivery times. Our customer gave us three days to propose a solution.

THE SOLUTION

Without benefit of any customer supplied drawings or specifications we engineered quality production tooling "as we went along", using clay and wooden mock-ups our customer supplied. Changes were frequent, often coming within hours of previous changes both from our customer and his customer. This unique, feature loaded scooter, priced well below competition, is currently being sold throughout the U.S. with our parts.

Without benefit of any customer supplied drawings or specifications we engineered quality production tooling "as we went along", using clay and wooden mock-ups our customer supplied. Changes were frequent, often coming within hours of previous changes both from our customer and his customer. This unique, feature loaded scooter, priced well below competition, is currently being sold throughout the U.S. with our parts.

THE PROBLEM

A firm developing a special effects fog machine needed vacuum formed plastic parts for their prototype machine. They also needed the prototypes assembled. Forty two different parts were involved. The coordination and assembly of purchased parts proved to be a nightmare.

THE SOLUTION

We assumed the complete production control scheduling and coordination of the customer's purchased parts. We vacuum- form the plastic parts, and assemble complete units which require fluid, electrical assembly, and plastic assembly skills. We currently supply finished product completely boxed and ready to ship.

We assumed the complete production control scheduling and coordination of the customer's purchased parts. We vacuum- form the plastic parts, and assemble complete units which require fluid, electrical assembly, and plastic assembly skills. We currently supply finished product completely boxed and ready to ship.

THE PROBLEM

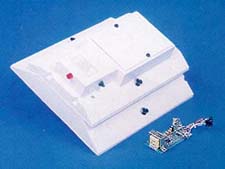

This unique, patented electronic trap for industrial use was being produced off shore to reduce assembly costs. Quality problems included inconsistent parts fit during assembly and erratic operation due to purchase of electronic parts from different suppliers, including home hobbyist sources. These problems resulted in serious delivery and warranty problems.

THE SOLUTION

Our analysis of the product resulted in the reengineering of the product's plastic parts for faster assembly and fewer parts loss. Our reengineer of the electronic circuitry resulted in consistent electrical operation as well as adhering to its specifications. In addition to performing our own field testing, we assisted the customer and his distributors to do the same. This resulted in the minor reengineer of several plastic and electrical parts which provided a substantial improvement in the products' operation and reliability.

Our analysis of the product resulted in the reengineering of the product's plastic parts for faster assembly and fewer parts loss. Our reengineer of the electronic circuitry resulted in consistent electrical operation as well as adhering to its specifications. In addition to performing our own field testing, we assisted the customer and his distributors to do the same. This resulted in the minor reengineer of several plastic and electrical parts which provided a substantial improvement in the products' operation and reliability.

If you would like an instant quote, use our information

request form

to send us a description of your part or product.

![[ SF Technology Home Page ]](images/smsft.gif)

Content - © 1998 - SF Technology, Inc. - All Rights Reserved

webmaster@sftech.com